Flexible options for OEMs of all sizes

Hydra Research is a small 3D printer manufacturer based in Portland, Oregon, USA. They offer open-source 3D printers, on-demand 3D printing services, and are currently ramping up to launch the Minnow, a brand-new 3D printer product line featuring an E3D Hemera extrusion system.

The Minnow by Hydra Research, designed for great results without tinkering

Hydra Research’s design goals for the Minnow were to produce a reliable, easy-to-use 3D printer that can print flexible filaments with precision out of the box. It’s intended as a workhorse for print farms, a desk companion for engineers and designers, or a powerful educational tool. Open-source Duet electronics enable users to easily modify the firmware to adapt it to individual use cases.

3D printing flexible filaments with precision

Flexible filaments are challenging to 3D print. Some extrusion systems need parts swapped around to use them, or are limited to specific flexible filaments with a high Shore A hardness to work reliably.

One of the biggest design challenges for Hydra Research was sourcing an extrusion system that could reliably 3D print rigid materials like PLA, ABS, and CPE, and flexible filaments without the need to reconfigure any parts of the machine. Thanks to Hemera, Hydra Research customers can achieve best in-class 3D printing speeds with flexible materials, and excellent performance with more rigid filaments too.

John Kray, the founder and CEO of Hydra Research, explains: “We saw a demand from our clients for a reliable, easy-to-use 3D printer that also prints flexible materials with precision out of the box. Hemera fits perfectly into that goal. We considered similar all-in-one extruder HotEnds on the market, but the combo of quality and value for money offered by Hemera won out.”

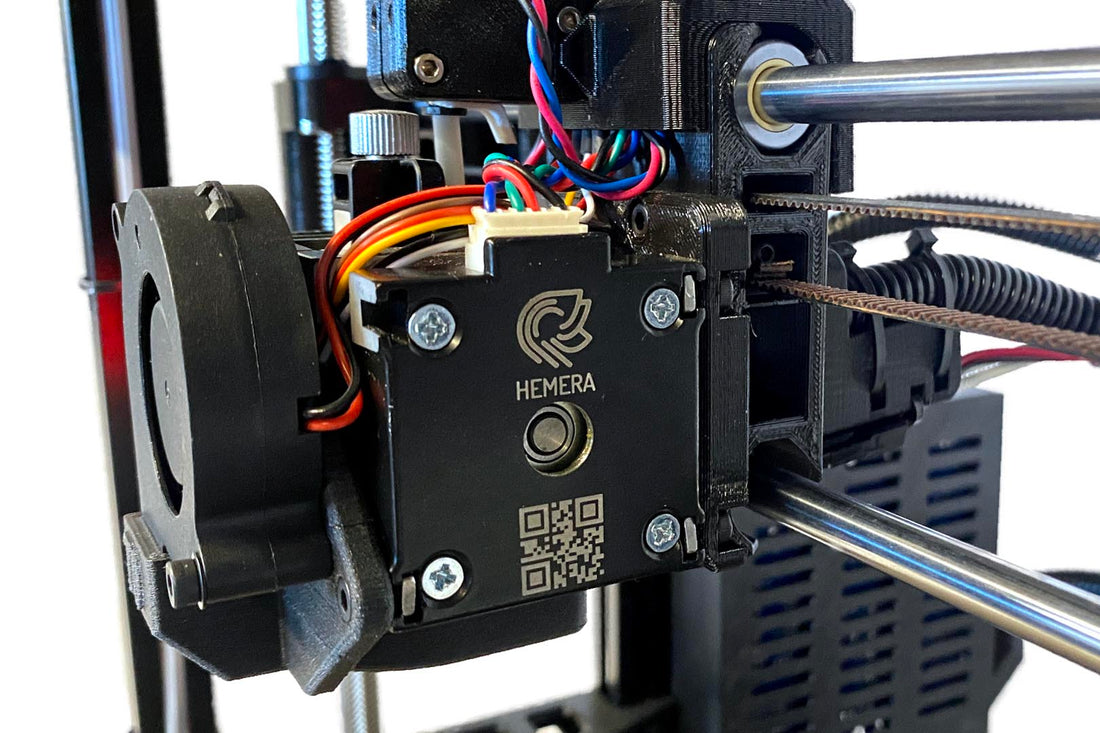

Each Minnow 3D printer features an E3D Hemera extrusion system, for excellent performance with rigid 3D printing materials and flexible filaments

Shrinking product development time and costs

As Hydra Research is a small company, outsourcing extrusion system manufacturing to E3D had its advantages:

- Using Hemera mitigated Hydra Research’s engineering risk. Buying a market-proven extrusion system is much more economical than developing a new extrusion system from scratch, which can cost tens of thousands in R&D alone and adds significant development time.

- Hydra Research could focus their R&D efforts on developing the rest of their hardware platform, developing software integrations, and forming strategic partnerships.

- Because Hydra Research are partnered with E3D, they have exclusive access to attractive discount options on Hemera stock.

“Without companies like E3D, we simply would not have the resources and the time to develop a reliable extrusion system in-house. Integrating Hemera has allowed us to put our limited resources towards building a robust hardware platform, along with software integration in Ultimaker Cura and our unique service contracts. This makes us an extremely competitive choice for businesses and schools who need an all-in 3D printing solution.”

- John Kray, Founder/CEO, Hydra Research

The Minnow by Hydra Research – coming soon!

Read more about the Minnow on Hydra Research’s product page.

Partner with us

At E3D, we’re happy to help 3D printer OEMs of all sizes. We offer off-the-shelf systems, modified systems, or completely custom systems to fit your machine. Get in touch to find out how we can help with all your extrusion system needs.