Written by Will Hardy

28/02/2023

Want to change to a different nozzle size in PrusaSlicer but aren’t sure which slicer settings to change? - Read on.

Setting up a slicer profile for a new nozzle size

Changing nozzle sizes on your FDM 3D printer can be a gamechanger for your creativity and workflow. It literally expands the capabilities of your machine. You’ll be able to print faster, print more detailed models or even make stronger parts.

Most slicers are already catering for the possibility of nozzle changing on their machines and with quick-change innovations like RapidChange Revo popping up, this facilitation is only going to increase.

We’ll be using PrusaSlicer as the slicer of choice for this blog, but the premise is the same for any other slicer software too.

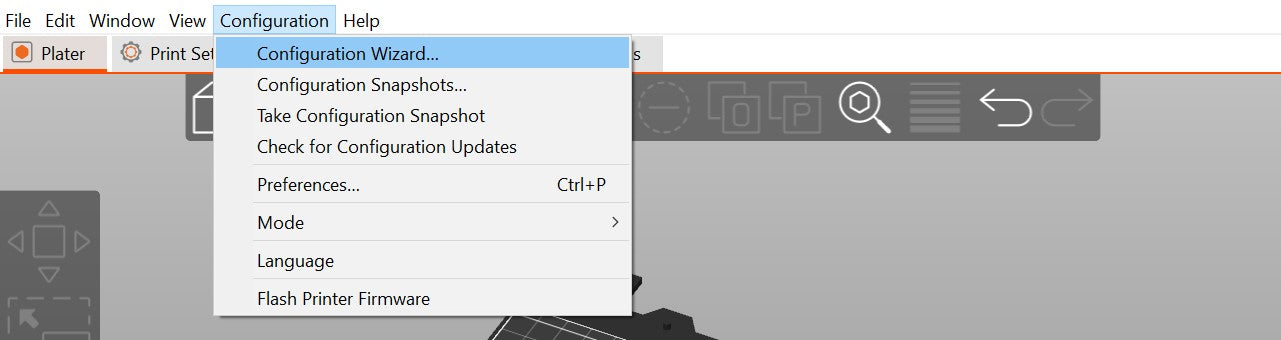

The first thing to check is if there is already a pre-existing profile for your 3D printer set up for the nozzle size you want to use. You can easily check this in PrusaSlicer by using the configuration wizard.

If your nozzle size isn’t supported, you’ll need to make a few changes to your existing profile to get it working with a new nozzle diameter. This isn't a guide to achieving perfect print quality, but it should get you quickly set up with a new nozzle diameter.

How to set up a new print profile for a larger Nozzle

Your printer most likely arrived with a 0.4mm nozzle pre-installed. This is the most common nozzle size and for most desktop machines, it offers a nice balance of speed and print quality.

Warning: When you start tweaking your current slicer settings, make sure to save the profile with a new name so you don’t override your original settings.

If you were to swap to a different nozzle size (e.g. 0.8mm) here are some settings that you will need to update:

📷 Make sure you have Expert selected in the top right-hand corner.

Layer Height and Extrusion Width

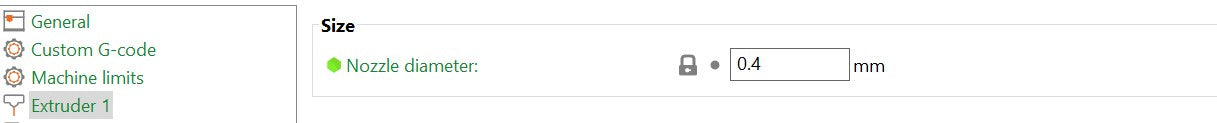

To alter extrusion width, you should start by changing your nozzle diameter to the new size. You can find this in printer settings under Extruder 1.

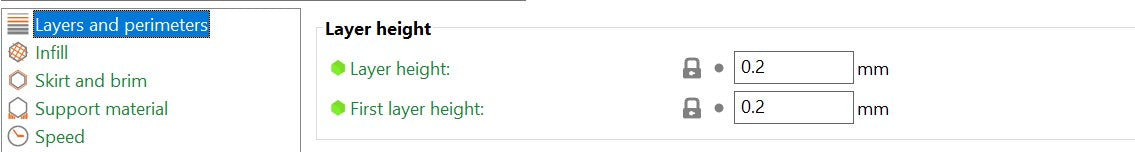

Layer height can be found under the Print Settings menu in PrusaSlicer, under 'Layers and perimeters'. A typical layer height is half of your nozzle diameter but feel free to go lower for a better surface finish and higher for a faster print time.

Then head to advanced, under Print Settings and change all values to 0. This allows these values to be set automatically each time you change the Nozzle diameter setting.

These settings denote the amount of material that should be extruded from the nozzle. They are the most important values to remember when switching nozzle sizes.

Note: Your layer height can be a maximum of 75% of your nozzle diameter. Higher than this and your layer adhesion will suffer. [For a 0.8mm nozzle, you can have a maximum of 0.6mm layer height]

Note: Your minimum extrusion width is the diameter of your nozzle, and your maximum is around 50% larger. Beyond this, you may start to see print quality issues. [For a 0.8mm nozzle, you can have a minimum extrusion width of 0.8mm and a maximum of 1.2mm]

Print Temperature

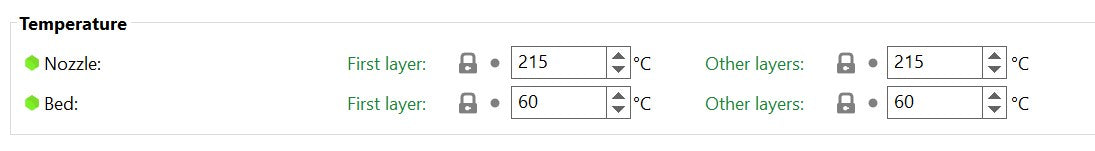

Temperature settings can be found in Filament Settings in PrusaSlicer under 'Filament'.

For optimal print quality when changing nozzle sizes, it can be beneficial to adjust your print temperature. Larger nozzle sizes running at the same print speeds will increase the flow rate required of the HotEnd. Therefore, if moving to a larger size, it can be beneficial to increase your print temperatures and vice versa.

So long as you are operating within your filament's recommended print temps, this is not an essential change, but if your prints are suffering from stringing or under extrusion, it’s one to look at.

Note: Try increasing the temperature by 10°C for under extrusion issues and try decreasing the temperature by 5°C for stringing. You can try larger values if necessary. You can use a temperature tower to do this.

Retraction

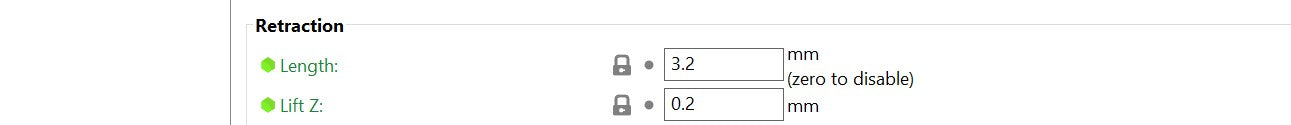

Head back to Extruder 1 under Printer Settings and look for the 'Length' setting under Retraction.

Another leading cause of print artefacts is incorrect retraction settings. Too high and you may notice gaps in your print, too low and you may notice excessive stringing. To check if your retraction settings are set correctly for your new nozzle size, try printing a model like this one which deliberately induces lots of retractions and print movements.

Note: Optimal retraction values can vary a lot depending on the distance between your Extruder and HotEnd (your filament path length). Bowden setups can have retractions of 3mm+ with Direct Drive being as low as 0.5mm in some cases. Any Direct Drive systems by E3D should not exceed a retraction value of 2mm, otherwise you risk jamming the HotEnd.

Print Speeds

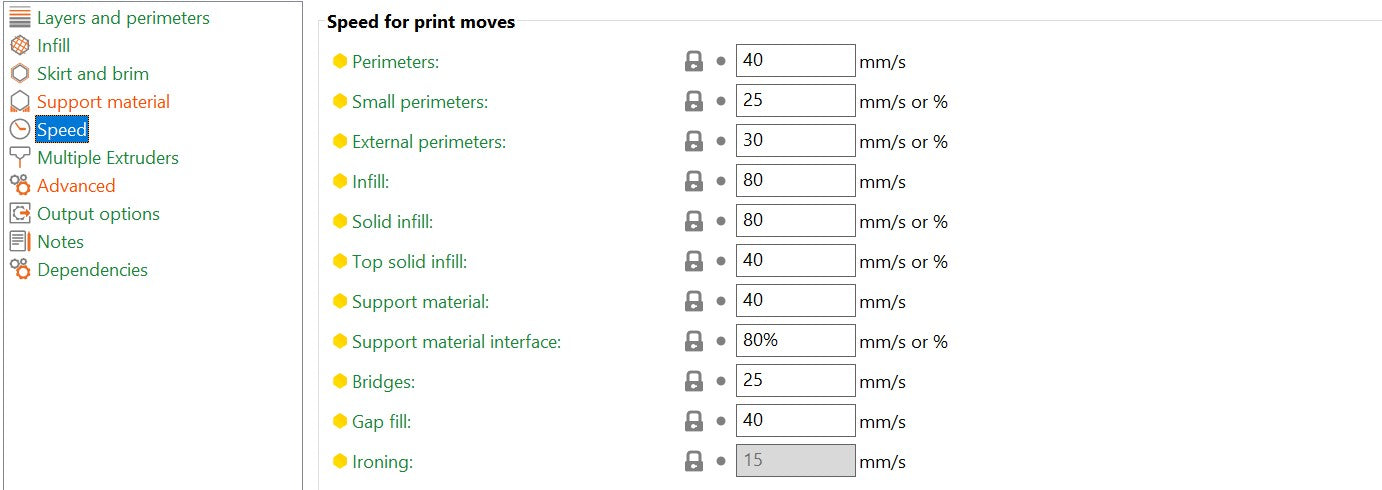

Print speeds are found in Print Settings under 'Speed'.

If you move to a larger nozzle size, you may find that you have exceeded your HotEnd’s maximum flow rate. Symptoms of this include gaps in your print, extruder clicking noises and weak layer bonding.

Note: By decreasing print speed, you lower your flow rate. Flow rate can also be increased by using a higher flow HotEnd.

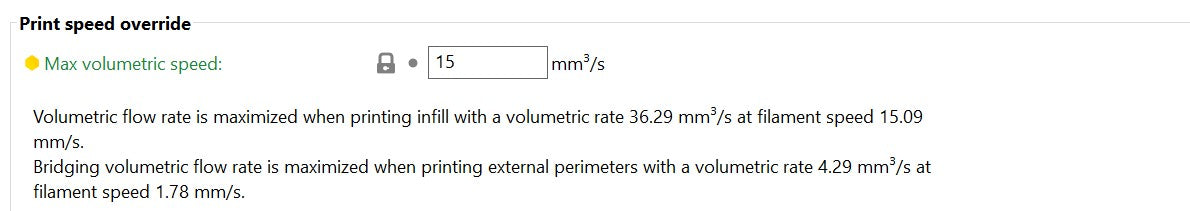

A simpler way to lower flow rate is to use this override. By lowering the number, all print moves are capped to ensure this flow rate is never exceeded. If you find out the maximum flow rate of your HotEnd, you can set it here to ensure you don't run into any flow problems. You can find flow rates for our Revo HotEnds here.